Oscillating Disc Rheometer

MOQ : 1 Unit

Oscillating Disc Rheometer Specification

- Shape

- Rectangular

- Control Type

- Microprocessor Controlled

- Temperature Resistance

- Up to 200C

- Speed Range

- 0.1 to 100 rpm

- Features

- High Sensitivity, Robust Construction, Programmable Testing, Emergency Stop

- Power Supply

- Electrical

- Heating Capacity

- Up to 200C

- Accuracy

- 0.1 Nm

- Display Type

- Digital LCD

- Usage

- Laboratory & Industrial

- Type

- Oscillating Disc Rheometer

- Dimension (L*W*H)

- Approx. 780 mm x 645 mm x 400 mm

- Product Type

- Oscillating Rheometer

- Equipment Materials

- High-grade Steel Alloy

- Power

- 220-240 V, 50/60 Hz, Single Phase

- Voltage

- As per required Volt (v)

- Application

- Laboratory & Industrial

- Warranty

- Yes

- Operating System

- Windows-Compatible Control Software

- Sample Loading Capacity

- Single/Double Test Specimen

- Test Chamber Diameter

- 176 mm

- Calibration

- Factory Calibrated with Options for User Calibration

- Color

- Industrial Grey

- Torque Measurement Range

- 010 Nm

- Ambient Temperature Range

- 10C to 40C

- Data Output

- USB and RS232

- Weight

- Approx. 70 kg

- Safety

- Overload Protection, Automatic Shutdown

- Testing Modes

- Automated & Manual

- Test Frequency

- 0.01 Hz to 10 Hz

- Compliance

- ASTM D2084, ISO 6502

Oscillating Disc Rheometer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 3 Units Per Month

- Delivery Time

- 6 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Oscillating Disc Rheometer

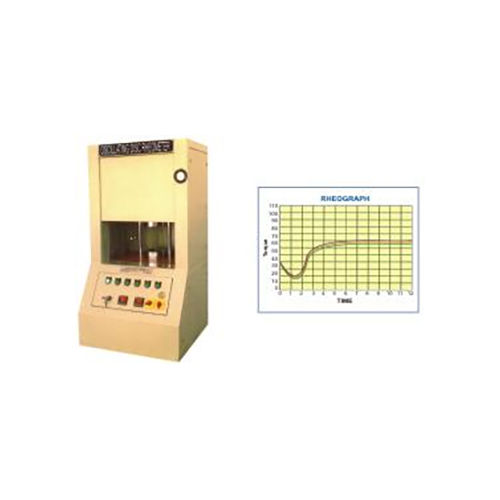

Oscillating Disc Rheometer shows a typical Cure Curve obtained in the software test screen. The curve of Torque V/s Cure Time depicts all the vulcanization characteristics of the Rubber Compound and that can be determined directly. XY Plot of Torque (F) against real cure time is called Rheometer graph. Rheometer graph is displayed in real time and at the end of test time, software and displayed on the screen.Precision & Reliability for Material Analysis

Engineered for rigorous laboratory and industrial applications, this Oscillating Disc Rheometer delivers precise torque measurements and programmable testing capabilities. The digital LCD interface and microprocessor controls facilitate easy operation and improved repeatability, ensuring dependable test results for rubber, polymers, and elastomers. Compliance with ASTM D2084 and ISO 6502 guarantees industry-standard performance.

Advanced Safety & User-Focused Design

The rheometer is equipped with advanced safety mechanisms such as overload protection, automatic shutdown, and an emergency stop, ensuring operator security during every test. The sturdy steel alloy build minimizes vibrations, while the devices compact rectangular shape (780 mm x 645 mm x 400 mm) fits seamlessly into modern laboratories or industrial facilities.

Flexible Operation and Data Management

With both automated and manual test modes plus USB and RS232 data outputs, this rheometer adapts effortlessly to varying laboratory protocols. Programmable testing features and Windows-compatible software deliver efficient data processing, seamless integration, and easy sharing or archiving of test results.

FAQs of Oscillating Disc Rheometer:

Q: How does the Oscillating Disc Rheometer ensure accurate measurements for my rubber compounds?

A: This rheometer uses high-sensitivity sensors, precise torque measurement (010 Nm, 0.1 Nm accuracy), and microprocessor control to deliver reliable results. Its factory calibration with user calibration options allows you to maintain accuracy for your specific testing protocols.Q: What types of test specimens can this device accommodate?

A: The rheometer supports both single and double test specimen configurations, making it adaptable for various research and quality control requirements in laboratories and industrial settings.Q: When should calibration be performed on the rheometer?

A: The instrument is factory calibrated, but user calibration can be performed as neededsuch as after significant relocation, mechanical adjustments, or periodically in line with your quality assurance protocols to maintain measurement accuracy.Q: Where can I use the Oscillating Disc Rheometer?

A: This device is designed for both laboratory and industrial environments. Its robust construction and broad temperature resistance make it suitable for diverse settings requiring precise elastomer testing, such as quality control labs or production facilities.Q: What is the process of conducting a test using this rheometer?

A: Begin by loading a single or double sample into the 176 mm test chamber. Choose automated or manual testing mode, set your testing parameters on the Windows-compatible software, and start the test. The results display on the digital LCD and can be exported via USB or RS232.Q: How does the Oscillating Disc Rheometer benefit laboratory workflows?

A: Its programmable, automated testing modes, high sensitivity, fast data output, and safety features minimize errors, maximize productivity, and streamline the analysis of rubber or elastomer properties for research and production control.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free