VSP And VHD Appartus

VSP And VHD Appartus Specification

- Max Height

- 60 cm

- Port Size

- 12 mm

- Test Range

- 0 - 1000 N

- Interface Type

- HDMI/USB

- Operating Voltage

- As per required

- Accuracy

- 1%

- Voltage

- As per required Volt (v)

- Operate Method

- Semi-Automatic

- Application

- Laboratory & Industrial

- Product Type

- VHD Appartus

- Specimen Size

- 50 mm x 50 mm

- Frequency

- 50 Hz

- Gas Pressure

- 0.6 MPa

- Hardness

- 30 - 90 Shore

- Resolution

- 0.1 N

- Display Type

- Digital

- Number of Specimens

- Up to 5

- Usage

- Laboratory & Industrial

- Features

- Semi-Automatic, Electric operation, Digital display, High precision measurement

- Measuring Range

- 0 - 1000 N

- Temperature

- 15C - 40C

- Response Time

- 1 second

- Mounting Type

- Bench-top

- Power Supply

- Electric

- Humidity

- 45% - 85% RH

- Automation Grade

- Semi-Automatic

- Capacity

- 1000 N

- Machine Weight

- 32 kg

- Test Speed

- 50 mm/min

- Test Width

- 100 mm

- Test Stroke

- 0-25 mm

- Control Mode

- Manual / Semi-Automatic

- Heating System

- Integrated (if required for testing)

- Data Output

- Digital & Manual logging

- Packaging Type

- Export Worthy Packing Box

- Calibration

- Factory calibrated with certificate

- Safety Features

- Overload Protection, Emergency Stop Button

- Material

- Stainless Steel & Powder Coated Components

- Equipment Type

- VSP & VHD Testing Apparatus

- Ambient Conditions

- Non-corrosive environment

- Compliance

- IS & ASTM Standards

- Power Consumption

- 80W

VSP And VHD Appartus Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 6 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About VSP And VHD Appartus

Standards: ASTM, ISO, IS

The Vicat softening point (VSP) is a measure of the temperature at which a plastic material softens and begins to deform under a specified load. It is a common test used in plastic testing laboratories to evaluate the heat resistance of plastic materials.

Reliable and Safe Material Testing

The VSP & VHD Testing Apparatus prioritizes both accuracy and operator safety. With robust overload protection and emergency stop features, users can perform testing procedures in accordance with IS & ASTM standards. Its stainless steel construction and powder-coated finish enhance durability, while export-worthy packing ensures secure transport.

Advanced Measurement Capabilities

Designed for precision, this apparatus delivers measurements with 1%% accuracy and a resolution of 0.1 N, displayed digitally for clear readability. It accommodates multiple specimens of 50 mm x 50 mm, supporting test speeds up to 50 mm/min and a capacity of 1000 Nideal for diverse laboratory and industrial applications.

Seamless Operation and Data Management

The machine is semi-automatic, enabling both manual and automated control. Data output can be logged digitally or manually, with options for HDMI and USB connectivity. Its factory calibration certificate ensures confidence in every test, while user-friendly controls simplify operation for laboratory staff and technicians alike.

FAQs of VSP And VHD Appartus:

Q: How does the VSP & VHD Testing Apparatus ensure testing safety?

A: The apparatus includes built-in overload protection and an emergency stop button, minimizing risks during operation. All components comply with IS & ASTM safety standards, and operation is optimized for non-corrosive environments.Q: What materials and specimen sizes can the equipment test?

A: It accommodates up to five specimens, each measuring 50 mm x 50 mm, with a measuring range of 01000 N. The robust design is suitable for testing a variety of materials commonly found in laboratory and industrial settings.Q: When is calibration required for the apparatus?

A: Every unit is factory calibrated and provided with an official calibration certificate. Re-calibration is generally recommended at regular intervals as per laboratory standards, or after extensive use, to maintain measurement accuracy.Q: Where can this testing machine be installed?

A: With its bench-top mounting type and compact design (max height 60 cm, machine weight 32 kg), it fits well into laboratories, quality control rooms, and industrial testing environments provided the ambient conditions are non-corrosive.Q: What is the process for capturing and managing test data?

A: Data can be logged digitally via the integrated digital display and interface ports (HDMI/USB), or manually. Operators can select manual or semi-automatic modes, ensuring flexibility in data management.Q: How is the apparatus operated and what are its power requirements?

A: It operates semi-automatically using electric power, requiring voltage as specified (compatible with different voltages globally) and consumes only 80W. Controls are intuitive, allowing both manual and semi-automatic adjustments.Q: What are the primary benefits of using this apparatus?

A: The equipment delivers high precision, rapid response (1 second), and conforms to international standards. Durable build and export-grade packaging make it suitable for both domestic and international use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber And Plastic Testing Equipment Category

Environmental Stress Cracking Resistance Apparatus Testers

Price Range 50000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Resistance Apparatus Testers

Voltage : As per required Volt (v)

Usage : Laboratory & Industrial

Specimen Size : 38 mm x 13 mm x 1.5 mm

Melt Flow Index Tester

Price Range 50000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Melt Flow Index Tester

Voltage : As per required Volt (v)

Usage : Laboratory & Industrial

Specimen Size : Standard test granules (approx. few grams)

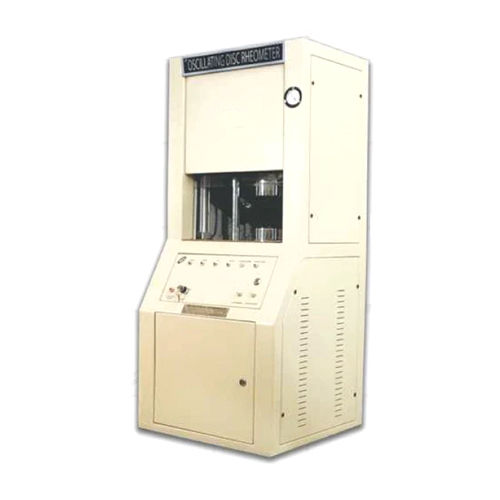

Oscillating Disc Rheometer

Price Range 100000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Oscillating Rheometer

Voltage : As per required Volt (v)

Usage : Laboratory & Industrial , Rubber Testing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free